Which sensors does Kaa use for hydrogen monitoring systems?

February 18, 2026Hydrogen safety starts at the sensor level, but it does not end there. Hydrogen presents a unique combination of risks that make sensor selection and system design inseparable. It is colorless, odorless, highly diffusive, and flammable across a wide concentration range. In the US, hydrogen monitoring is increasingly scrutinized under a combination of OSHA safety expectations, NFPA guidance, insurance requirements, and state-level permitting frameworks. While regulations typically specify what must be detected, they rarely dictate how monitoring should be architected. This leaves system designers responsible for making technically sound choices that balance detection accuracy, reliability, response time, and operational context.

A common mistake is treating hydrogen monitoring as a standalone gas-detection problem. It is a system-level challenge. A sensor may correctly detect hydrogen concentration in parts per million or as a percentage of the lower explosive limit (LEL), but without context (ventilation state, pressure conditions, operating mode, or historical behavior), the signal alone does not reliably indicate risk. False positives lead to alarm fatigue; false negatives lead to unsafe conditions. This is why modern hydrogen projects in the US are moving away from isolated detectors toward integrated monitoring systems. Sensor choice remains foundational, but its value depends on how sensor data is ingested, validated, correlated, and acted upon across distributed assets and remote sites.

Sensor-agnostic approach: How Kaa works with hydrogen sensors

KaaIoT approaches remote hydrogen monitoring as a data and control problem rather than a hardware product. The platform does not manufacture hydrogen sensors and does not prescribe specific sensor brands. Instead, it operates as a sensor-agnostic monitoring layer designed to integrate with certified industrial sensors already approved for use in hazardous environments. This approach is particularly relevant in the US market for several reasons. Many hydrogen projects, especially those involving energy infrastructure, transportation fleets, or industrial facilities, are built around pre-approved sensor vendors that meet ATEX, IECEx, or UL-related requirements. Replacing these sensors to satisfy a software platform would introduce unnecessary cost, certification delays, and compliance risk.

A sensor-agnostic architecture allows operators to:

- retain existing certified hydrogen sensors,

- mix vendors across sites without redesigning the monitoring stack,

- scale deployments incrementally as projects expand from pilot to commercial scale.

Kaa treats sensors as signal sources rather than “smart endpoints.” Whether hydrogen concentration data arrives via a 4-20 mA analog loop, a digital interface, a PLC register, or an industrial gateway, the platform focuses on normalizing, validating, and contextualizing that data before it becomes part of the safety decision flow. This separation between sensing hardware and monitoring intelligence is critical for long-term operability. Sensors age, drift, and require maintenance. Monitoring systems must be resilient to these realities without assuming ideal sensor behavior at all times.

Hydrogen sensor technologies commonly used with Kaa

Hydrogen monitoring systems built on Kaa typically integrate several well-established sensor technologies. Each has strengths, limitations, and appropriate use cases depending on environment, detection range, and operational constraints. The most common sensor types include electrochemical, catalytic (pellistor), thermal conductivity, and optical or solid-state sensors. No single technology is universally “best.” Effective systems often use different sensor types in different zones of the same facility.

Hydrogen sensor technologies and typical use cases

| Sensor type | Detection range & response | Typical environments | Strengths | Limitations |

|---|---|---|---|---|

| Electrochemical | Low ppm to low % LEL, fast response | Enclosed rooms, cabinets, indoor equipment | High sensitivity, good selectivity | Limited lifespan, affected by humidity & temperature |

| Catalytic (pellistor) | % LEL range, moderate response | Industrial zones, legacy installations | Robust, well-understood technology | Less sensitive at low concentrations, oxygen-dependent |

| Thermal conductivity | Broad concentration ranges | Pipelines, controlled industrial systems | Stable measurement of hydrogen-specific properties | Less effective in mixed-gas or variable environments |

| Optical / solid-state | ppm to % LEL, fast response | Outdoor sites, ATEX zones, long-life installs | Low drift, long service life | Higher cost, integration complexity |

Electrochemical sensors are commonly used where early detection is critical, such as enclosed electrolyzer rooms or compressor housings. Catalytic sensors remain widespread in industrial environments, particularly where historical standards and maintenance practices are already established. Thermal conductivity sensors are often applied in controlled process systems rather than ambient air monitoring. Optical and solid-state sensors are gaining traction in outdoor and remote installations due to their stability and long operational life.

From sensor signals to actionable hydrogen safety data

Detecting hydrogen concentration is only the first step. In real-world operations, actionable safety decisions depend on understanding why a sensor value changed and what it means in context. Kaa integrates hydrogen sensors through industrial data paths such as PLCs, data loggers, and edge gateways. Supported inputs include standard analog signals (4-20 mA, 0–10 V), digital interfaces, and protocol-based data from control systems. Once ingested, sensor data is validated at the edge to detect out-of-range values, signal dropouts, or abnormal behavior indicative of sensor malfunction.

Crucially, hydrogen sensor data is correlated with other operational signals. These may include ambient temperature, pressure readings, ventilation system status, equipment operating modes, or maintenance state. A brief hydrogen spike during a known purge cycle carries different risk implications than a similar reading during steady-state operation with inactive ventilation. This contextual processing is what differentiates monitoring from raw detection. Instead of issuing alarms solely based on static thresholds, the system can distinguish between:

- transient, non-hazardous concentration changes,

- gradual sensor drift requiring maintenance,

- genuine leak conditions requiring immediate response.

For US operators managing geographically distributed assets, such as hydrogen refueling stations, energy storage sites, or fleet depots, this capability is especially important. Remote monitoring teams must rely on data-driven confidence, not constant site-level intervention. Reducing false alarms while maintaining conservative safety margins improves both safety outcomes and operational efficiency.

Compliance, architecture, and sensor selection best practices

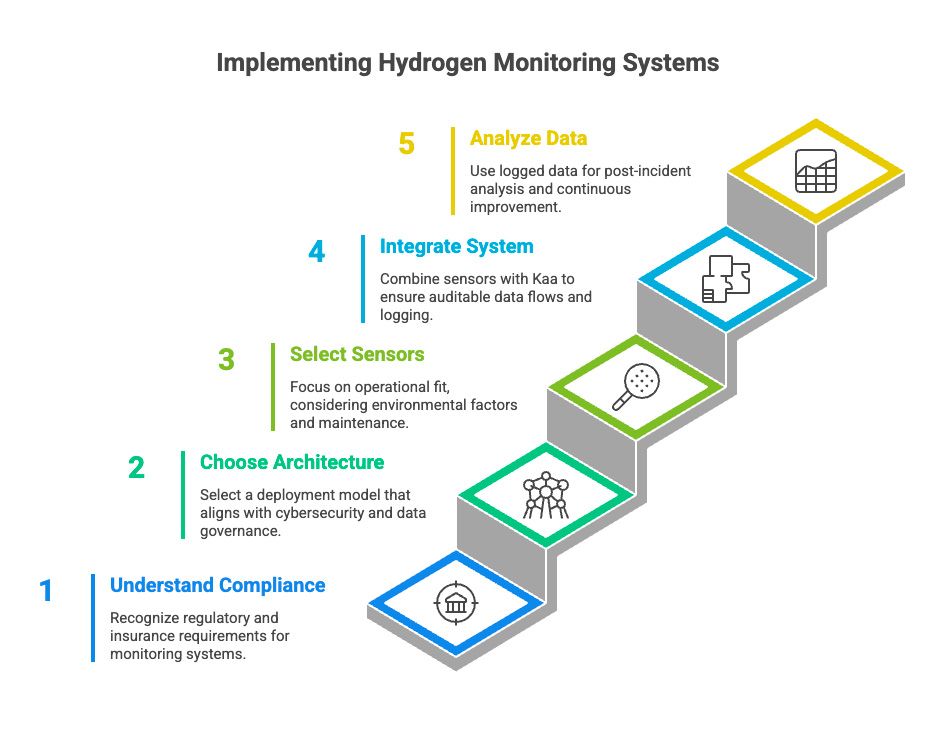

Hydrogen monitoring systems in the US operate within a complex compliance landscape. While specific sensor certifications (such as ATEX or IECEx) apply primarily to hardware, regulators and insurers increasingly expect demonstrable monitoring, logging, and incident traceability at the system level. Kaa does not replace certified sensors or assume their compliance responsibilities. Instead, it complements them by providing auditable data flows, historical records, and transparent alarm logic. This supports post-incident analysis, regulatory reporting, and continuous improvement without interfering with certified detection hardware.

From an architectural standpoint, common deployment models include single-site installations, distributed networks of refueling stations or storage assets, and hybrid environments combining on-prem and cloud components. Kaa supports these models by decoupling sensor integration from backend deployment, allowing operators to choose architectures aligned with cybersecurity policies and data governance requirements.

When selecting hydrogen sensors for a Kaa-based system, best practices focus on operational fit rather than theoretical performance. Key considerations include whether the environment is indoor, outdoor, or classified hazardous, required detection range and acceptable response time, maintenance intervals and calibration constraints, and compatibility with existing control infrastructure. Lifecycle cost often matters more than sensor purchase price. A slightly more expensive sensor with lower drift and reduced maintenance requirements may deliver better long-term safety and lower operational risk.

You may be interested in: Current state of the market: scale, growth, and forecasts for hydrogen transport

Closing perspective

Kaa does not “use” a fixed set of hydrogen sensors. Instead, it enables hydrogen monitoring systems that use the right sensors for the right environments without locking operators into specific vendors or technologies. This flexibility is essential. Provided that hydrogen projects scale from pilots to infrastructure-grade deployments, monitoring systems must evolve alongside them. Sensor-agnostic architectures, contextual data processing, and compliance-ready monitoring are prerequisites for safe, scalable hydrogen operations.