Kaa Hydrogen Remote

Monitoring Solutions

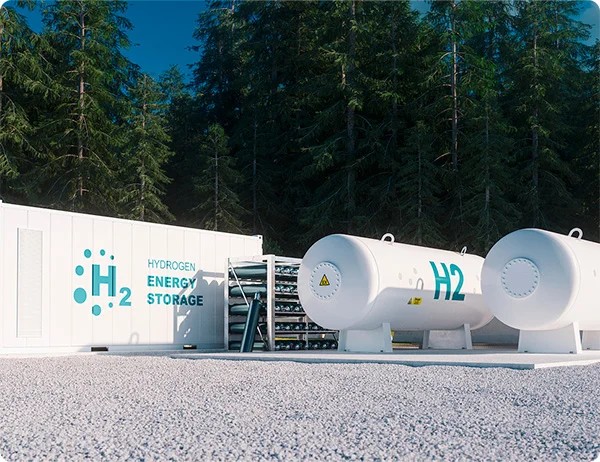

Real-time safety, compliance, and uptime for hydrogen infrastructure

Kaa provides a secure and scalable hydrogen monitoring system that tracks electrolyzers, compressors, storage tanks, and dispensers in real time. With continuous data capture, predictive analytics, and remote access, operators can reduce unplanned downtime, meet safety standards, and keep fueling capacity available around the clock.

Request a demoWho Benefits from Our Solution

Companies that build hydrogen electrolyzers

Prove higher reliability with remote monitoring and cut warranty service costs. Kaa helps equipment manufacturers integrate hydrogen monitoring equipment directly into their systems, enabling predictive maintenance and extended asset life.

Companies that make station components

Detect issues before they cause failures – protect uptime and maintain a strong reputation. With a connected H2 monitoring system, suppliers of compressors, storage tanks, and dispensers can provide safer, more reliable hardware backed by IoT-driven insights.

Fleet operators using hydrogen vehicles

Keep vehicles fueled and on the road – no surprises, no delays. Fleet managers gain peace of mind through hydrogen leak detection and remote monitoring, ensuring fast fueling, safe operation, and minimized downtime.

Core Capabilities

See everything live

Monitor the condition of electrolyzers, compressors, tanks, and dispensers on a single dashboard. Get immediate alerts when equipment drifts from expected performance.

Run safer stations

Record and analyze operational data to demonstrate compliance with industry guidelines such as ISO 19880-1 and NFPA 2, reducing risk during inspections and audits.

Faster fixes, less downtime

Spot early warning signs of failure with AI-powered anomaly detection. Dispatch technicians only when necessary, reducing service costs and minimizing unnecessary site visits.

Update equipment remotely

Push secure firmware and software updates over the air to keep devices optimized and aligned with the latest safety requirements.

Powerful Features at Your Service

Intelligent Monitoring

Kaa provides dashboards built for hydrogen equipment: electrolyzers, compressors, tanks, and dispensers. Operators can track pressure, flow, temperature, and efficiency in real time, using drag-and-drop widgets for quick visualization. AI tools identify leaks, abnormal cycles, or inefficiencies before they escalate into failures. A built-in asset management module provides a single view of all connected devices, while the rule engine enables both simple alerts and advanced automation. Notifications are delivered via email, SMS, or phone calls to ensure that the right people act fast.

Remote Access & Management

Kaa enables secure, role-based remote access to hydrogen monitoring equipment and connected gateways. Teams can run real-time diagnostics, adjust configuration, or push firmware updates without sending staff onsite. All communication is protected by TLS-encrypted MQTT and VPN tunnels, providing operators with confidence that sensitive data remains secure. Multi-tenant workspaces allow different teams or contractors to collaborate safely, making the system scalable for networks of stations or fleets.

IoT Connectivity Gateway

At the edge, Kaa relies on an advanced industrial MikroTik gateway designed for seamless integration with hydrogen station infrastructure.

- Supports Modbus, LoRaWAN, BLE, LTE, NB-IoT, and MQTT

- Linux-based for fast customization

- TLS encryption & VPN for secure data transmission

- DIN rail-mounted for industrial deploymen

Reasons to Get Started

Free Trial

Each hardware purchase includes a 3-month free trial of Kaa software, which lowers adoption barriers and gives operators time to validate results.

Fast ROI

Predictive maintenance reduces downtime and service costs, delivering a measurable return on investment within a matter of months.

Developer Support

Kaa provides dedicated technical assistance to expedite custom integrations and help teams launch tailored monitoring solutions more quickly.

Remote Access

With secure VPN connectivity, operators gain real-time diagnostics, firmware updates, and configuration management, reducing travel costs and keeping assets optimized.

Hardware + Software Subscription Model

Kaa offers a hardware + software subscription model that ensures seamless integration and predictable costs. Each hardware purchase includes a 3-month free trial of the platform, after which customers can select monthly or annual plans. For partners, we provide royalty-based programs that open new revenue streams by bringing IoT-enabled monitoring, predictive maintenance, and remote control into their service portfolios.

Scaling Hydrogen Infrastructure Safely

with Centralized Monitoring

Hydrogen fueling stations and production sites face constant challenges: keeping electrolyzers, compressors, and dispensers online, meeting strict safety codes, and preventing costly leaks. Manual inspections alone can’t provide the continuous visibility required for today’s operations. A connected hydrogen monitoring system closes this gap.

With Kaa, operators gain a centralized H2 monitoring system that aggregates data from all station assets. Dashboards track pressure, flow, and temperature, while AI-driven alerts flag anomalies early, from compressor wear to abnormal storage tank cycles. Built-in hydrogen leak detection and H2 leak detection capabilities help prevent incidents, protect staff, and reduce liability.

The platform also supports hydrogen sulfide monitoring equipment, making it suitable for facilities where mixed-gas environments add complexity. Open APIs connect monitoring data with maintenance and ERP tools, ensuring smooth workflows. Remote access, firmware updates, and VPN-secured connections further reduce downtime and service costs.

For companies that build electrolyzers, supply station components, or run hydrogen fleets, Kaa delivers a proven way to improve safety, protect uptime, and scale operations with confidence.

Book a demo

Book a demo