Industrial boiler troubleshooting and remote monitoring tips

October 29, 2025Industrial boilers rarely get the spotlight until something goes wrong. They quietly keep factories running, hospitals warm, and energy systems stable. But when a boiler fails, production stops, alarms go off, and every minute starts costing money. Even the best-maintained units aren’t immune to wear, corrosion, or pressure drops after years of hard work. The difference between a quick fix and a full shutdown often comes down to timing, how early you spot the warning signs. That’s where remote monitoring changes everything. With real-time data on temperature, pressure, and flow, teams can see what’s happening inside the system long before a fault shows up on-site.

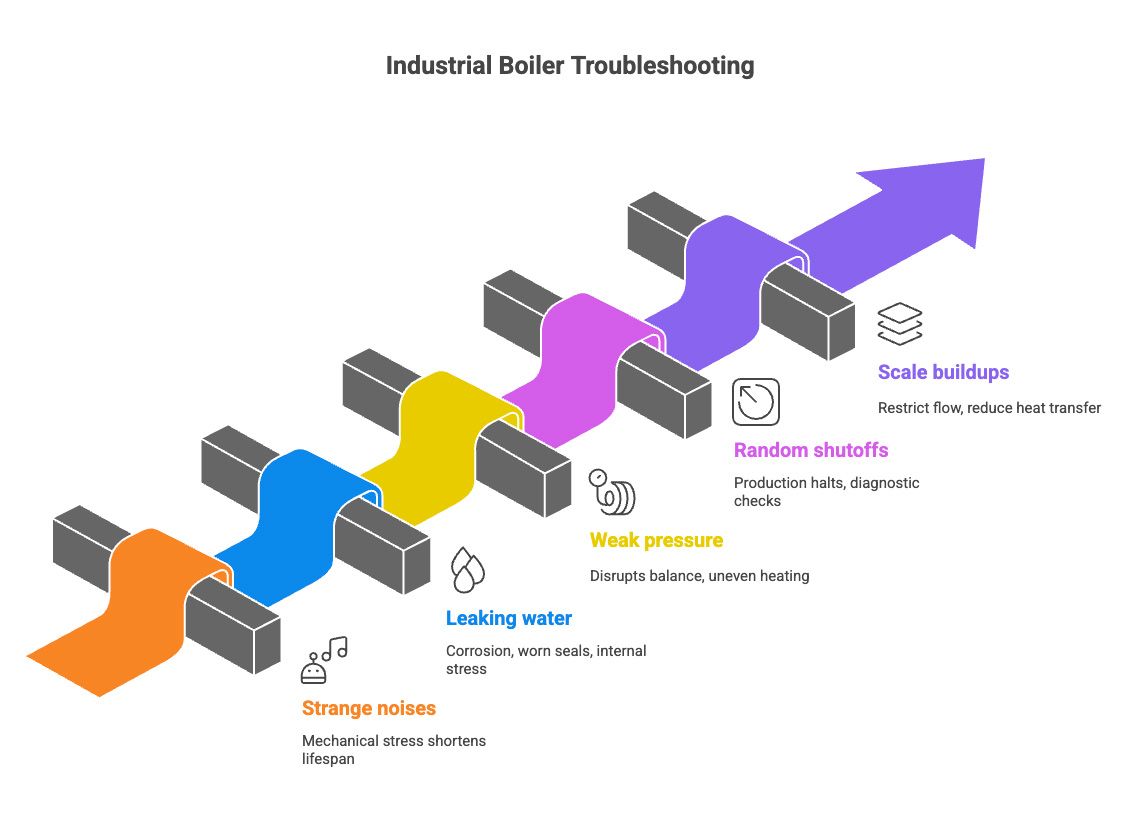

Let’s look at the most common industrial boiler troubleshooting issues and how remote monitoring makes them easier to predict, prevent, and resolve.

Common boiler problems

While boilers are designed for decades of operation, small issues can quickly escalate if left unchecked. Responding early minimizes downtime and saves on costly repairs. Below are five frequent industrial boiler troubleshooting scenarios and how water heater and remote boiler monitoring systems can help detect and prevent them.

1. Strange noises

Unexpected sounds such as whistling, banging, or rumbling are often an early indicator that something inside the boiler is not functioning as it should. These noises may result from trapped air, sediment buildup, low water levels, or uneven heating surfaces caused by limescale deposits. Left unresolved, such vibrations create mechanical stress that shortens the lifespan of internal components and can lead to serious damage over time.

Operators should pay attention to when and where the noises occur. Whistling often indicates low water pressure or restricted flow, while rumbling may signal boiling water trapped beneath scale deposits. Regular flushing, proper venting, and consistent water chemistry management are effective preventive measures.

Modern remote diagnostics can detect these subtle mechanical anomalies long before they become audible to the human ear. By combining vibration and acoustic sensors with temperature and pressure data, monitoring platforms create a real-time “health profile” of the boiler. When abnormal frequency patterns appear, the system notifies operators and correlates the event with other parameters, such as pressure surges or pump cycles, to pinpoint the cause. This data-driven insight allows maintenance crews to correct imbalances or clean the heat exchanger before noise turns into damage, extending both safety and equipment life.

2. Leaking water

Leaks are one of the most common and disruptive issues with boilers. Even a small amount of water escaping from joints or fittings can signal corrosion, worn seals, or internal stress. In severe cases, tank leaks indicate wall erosion caused by poor water treatment or prolonged exposure to oxygenated feedwater. Once the tank’s integrity is compromised, replacement is typically the only safe option.

However, not all leaks require complete replacement. Minor problems, such as a cracked expansion tank, faulty pressure relief valve, or worn gasket, can often be repaired quickly. In closed-loop systems, leaks may also appear along distribution lines or condensate returns, gradually reducing pressure until the boiler shuts down.

Common signs of developing leaks include

- Gradual loss of system pressure or frequent refilling

- Water pooling near the base or connecting pipes

- Corrosion or mineral stains around fittings

- Air ingress causing noise or uneven heating

Remote monitoring technologies make leak detection proactive rather than reactive. Continuous readings from flow, level, and pressure sensors reveal early deviations from regular operation. Once anomalies appear, operators receive instant alerts and can remotely reduce pressure or isolate affected lines, preventing water loss, structural damage, and costly downtime while extending equipment life.

3. Weak or slow-building pressure

Inconsistent or slow pressure buildup usually points to hidden leaks, faulty steam traps, or feed pump malfunctions. These issues can disrupt the delicate balance between water supply, combustion rate, and steam generation, causing uneven heating across the facility. Pressure instability doesn’t just affect comfort; in industrial applications, it can lead to production inefficiency or safety risks from sudden overpressure events.

A typical first step in troubleshooting is to inspect for leaks in joints or fittings and check that the feedwater pump and steam traps function properly. Dirty filters, blocked return lines, or undersized pumps can also contribute to weak pressure. Consistently low readings on the pressure gauge are a signal to investigate before operational continuity is compromised.

In connected boiler environments, remote control systems continuously track real-time pressure curves and automatically adjust control valves, burners, or pumps to restore balance. Instead of waiting for manual readings, operators receive immediate alerts if pressure deviates from optimal thresholds. Historical data trends reveal gradual declines that may otherwise go unnoticed, helping to predict when a seal or valve is wearing out. By combining data analytics with automated correction, these systems turn unstable pressure behavior into a manageable, trackable variable rather than a disruptive emergency.

4. Random shutoffs

Unexpected shutdowns are among the most disruptive issues in industrial boiler operations. They can be triggered by malfunctioning thermostats, damaged pumps, sensor faults, or sudden loss of airflow or fuel supply. When a boiler stops mid-cycle, production halts, and the system must undergo diagnostic checks before restarting – a process that costs both time and energy.

The complexity of modern boilers means that a single failure can cascade into multiple alerts. Manual troubleshooting often requires on-site inspection of thermostats, control circuits, and safety interlocks. However, waiting for technicians to arrive can extend downtime and increase operational losses.

This is where integrated remote monitoring and control make a critical difference. These platforms automatically record every parameter at the moment of shutdown, including combustion pressure, gas flow rate, feedwater level, and sensor data, allowing operators to pinpoint the exact cause from a central dashboard. Some systems even permit authorized personnel to remotely restart the boiler after confirming safety conditions, dramatically reducing downtime. Over time, this log data helps uncover recurring failure patterns, whether related to fluctuating air pressure, electronic controls, or aging components, enabling predictive replacement before another outage occurs. What used to be a sudden and costly surprise becomes a well-documented, manageable process.

5. Blockages or scale buildups

Over time, even well-maintained boilers can develop mineral deposits inside tubes, valves, and pressure vessels. Poor water quality is the most common cause: hard water introduces calcium and magnesium, which crystallize into scale under high heat. These deposits restrict flow, reduce heat transfer, and force the boiler to burn more fuel to achieve the same output. In steam systems, scale buildup can also trap heat unevenly, creating dangerous hot spots that stress metal components.

If left unattended, blockages eventually reduce or halt circulation. This can lead to overheating, pressure imbalance, and accelerated wear on pumps and seals. Regular chemical treatment and blowdown cycles help prevent these buildups, but detection between scheduled inspections remains difficult.

With a remote industrial boiler monitoring system, operators can spot early warning signs before the problem becomes mechanical. By analyzing changes in thermal efficiency, heat-up time, or pressure differentials across sections, the system detects restricted flow long before a blockage forms. Some platforms integrate water quality sensors to measure hardness and conductivity, automatically alerting teams when chemical balance drifts outside safe ranges. This allows maintenance to intervene early, cleaning heat exchangers or adjusting dosing, without waiting for performance to degrade or energy costs to spike.

Troubleshooting boiler issues

While complex failures require a certified technician, many industrial boiler troubleshooting steps can be performed in-house, especially with the support of digital monitoring systems.

- Use a remote boiler interface. Smart interfaces display performance metrics, issue alerts, and even recommend corrective actions. They transform maintenance from reactive to proactive, which is key to extending asset life and optimizing fuel efficiency.

- Check system pressure. Monitor both temperature and pressure levels to ensure they fall within operational specifications. Remote dashboards make this data accessible from anywhere, allowing real-time adjustments.

- Verify sensor accuracy. A faulty gauge or sensor can distort readings. Modern monitoring systems flag sensor drift or calibration issues, ensuring decisions are based on accurate data.

- Inspect water quality. Poor water treatment accelerates corrosion and scaling. Remote water analysis and automated chemical dosing can maintain proper pH and conductivity levels without the need for manual testing.

- Schedule regular maintenance. Predictive maintenance platforms analyze operational trends to forecast when cleaning, inspection, or part replacement is due, thereby reducing the need for emergency repairs.

You may be interested in: Industrial Boiler IoT: Full-Scale Architecture and Operations Deep Dive

Conclusion

Once the issue is identified, timely repair is crucial. Partnering with experienced boiler technicians ensures problems are resolved safely and effectively. However, the best long-term protection comes from integrating industrial boiler remote monitoring with your maintenance plan.

Remote systems provide 24/7 visibility into pressure, temperature, flow, and combustion data, allowing operators to address small deviations before they escalate into shutdowns. When combined with periodic on-site inspections, this hybrid approach reduces unplanned downtime, lowers fuel costs, and extends the lifespan of the boiler. It’s the foundation of safer, more efficient industrial boiler maintenance.