Industrial Boiler IoT: Full-Scale Architecture and Operations Deep Dive

Introduction

Managing industrial boilers and water-heating installations in the United States comes with well-known challenges:

- Unstable or absent internet at production sites

- Corporate firewalls and complex network policies

- Stringent security requirements for data and remote access

At the same time, engineers must continuously monitor temperature, pressure, fuel consumption, combustion quality, and the overall condition of equipment to maintain efficiency and safety.

KaaIoT is an industrial IoT platform that addresses these challenges. It unifies data collection, analytics, access control, and visualization in one solution, enabling industrial boilers to be connected to IoT quickly, securely, and without complicated hardware customization.

For companies with strict data-protection requirements, KaaIoT offers three deployment options:

- Cloud – a fast start with no capital expenditures and automatic scaling

- Hosted – a dedicated, fully managed instance for organizations requiring an isolated environment without in-house administration

- Self-Hosted – a full deployment inside the customer’s own infrastructure (for example, on Supermicro servers) for complete control over data and processes

The latter two approaches suit organizations where data privacy and independence from the public cloud are critical.

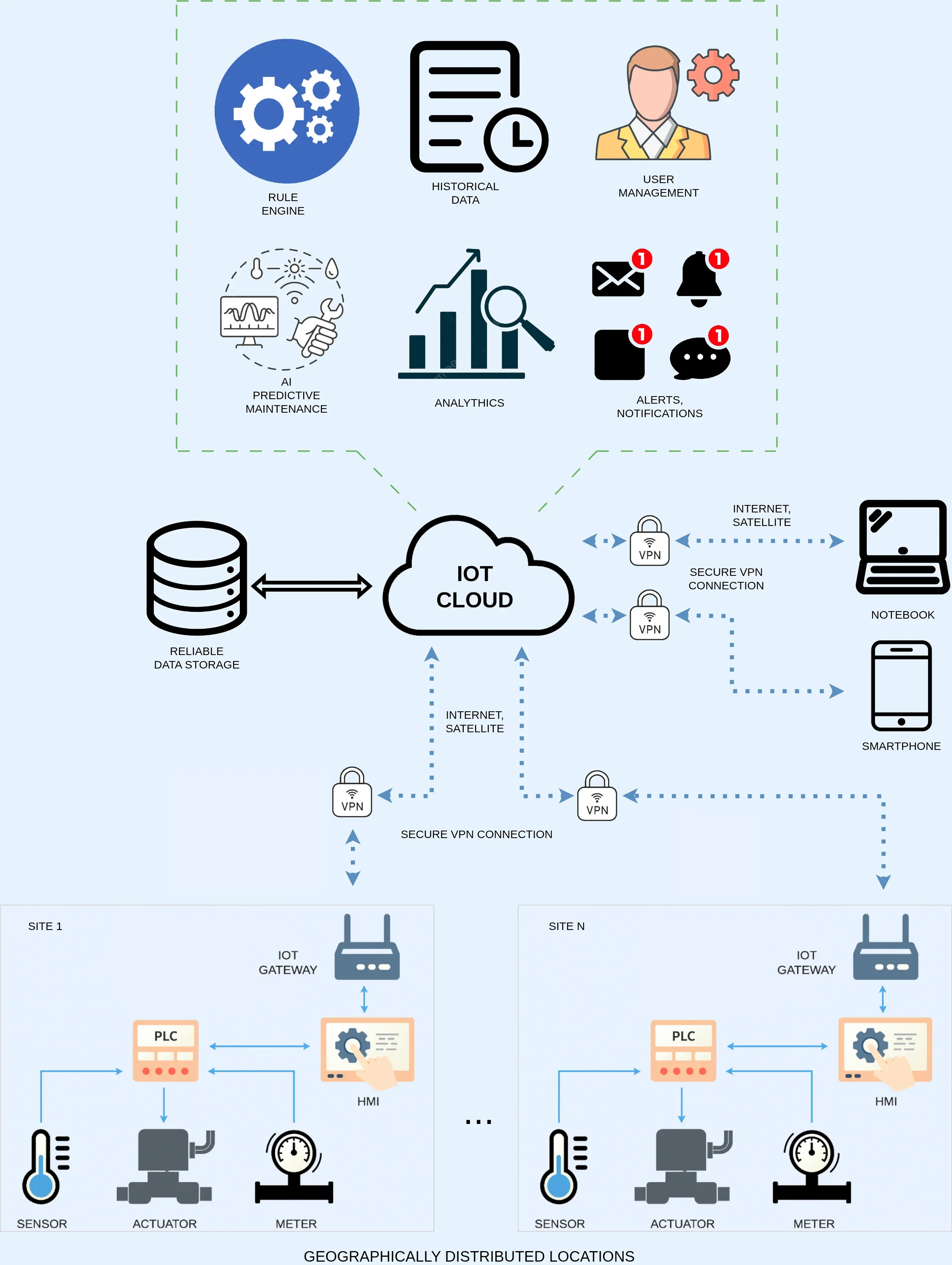

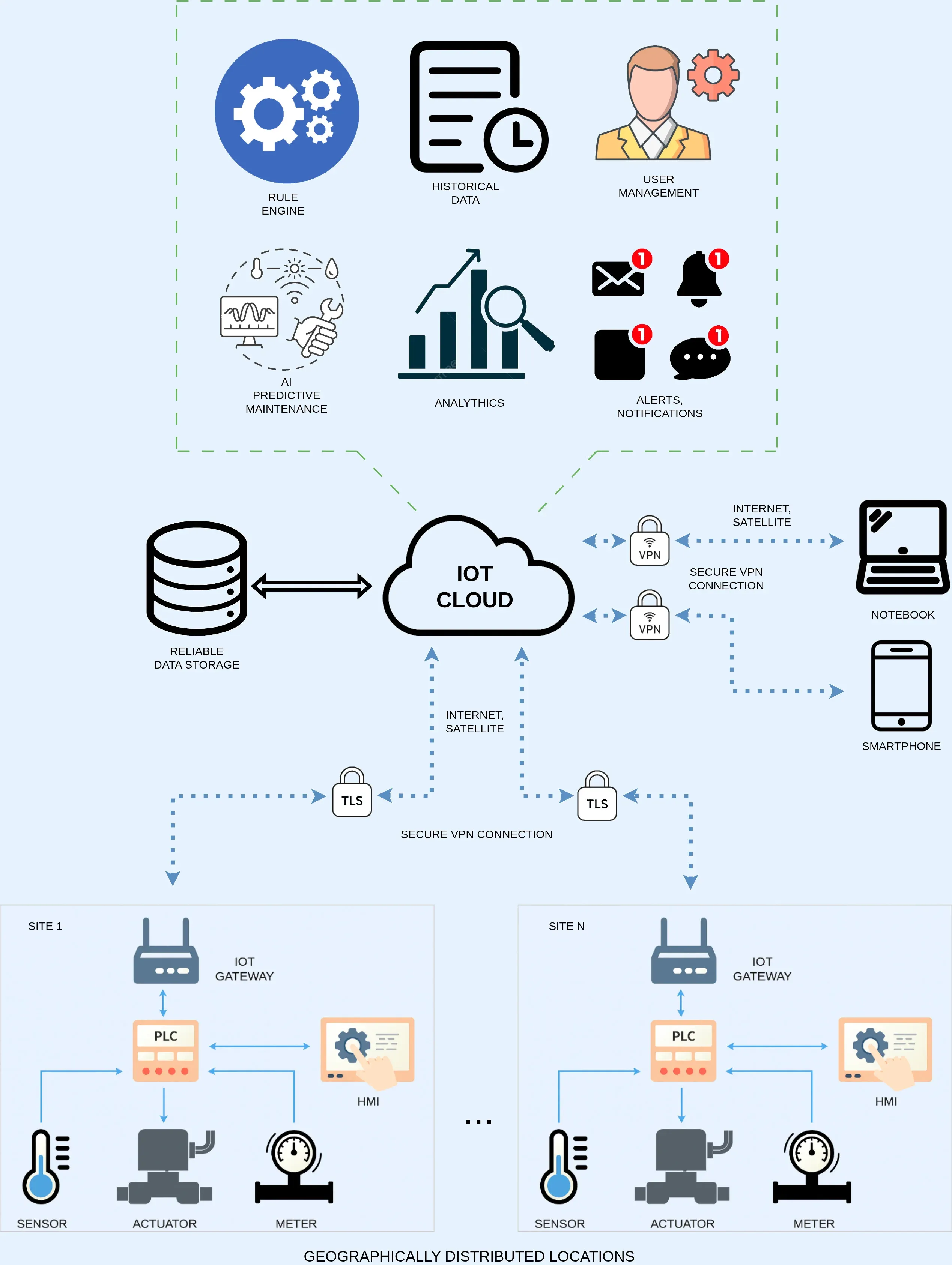

Solution Architecture

Data flow is possible in two variants.

Connection to the HMI VNC:

Sensors → Controller → HMI (VNC) → Gateway (MikroTik) → KaaIoT VPN → MQTT Broker → KaaIoT Core → KaaIoT Dashboard

Connection to the PLC:

Sensors → Controller → Gateway (MikroTik/Teltonika) → KaaIoT VPN → MQTT Broker → KaaIoT Core → KaaIoT Dashboard

Each element of this chain plays a specific role in delivering reliable monitoring and control.

1. Sensors

Responsible for capturing all key parameters and events:

- Boiler metrics – steam pressure, water and steam temperature, fuel and water flow, oxygen content in flue gases

- Environmental metrics – room temperature and humidity, CO/CO₂ concentration, smoke or gas leaks

- Access metrics – door-open sensors, RFID readers, magnetic locks

- Video monitoring – IP cameras for visual oversight

Data is collected every few seconds to several minutes and immediately passed to the controller.

2. Controller

Collects data over Modbus RTU/TCP, preprocesses it, and forwards it both to the local HMI and to the gateway for delivery to the cloud or on-premises KaaIoT deployment.

3. HMI (VNC)

The human–machine interface, accessible remotely via VNC. Engineers see an exact replica of the local control panel in a browser and can manage the equipment securely without traveling to the site.

4. Gateway

Converts Modbus data to MQTT messages and provides reliable communication with the platform. Supported off-the-shelf devices include: MikroTik KNOT LR8 Kit and Teltonika for Modbus.

5. KaaIoT VPN

Establishes an encrypted tunnel over LTE or wired internet, allowing secure operation even behind corporate firewalls and in unstable networks.

6. MQTT Broker

Receives data from the gateway and forwards it to KaaIoT Core for processing and visualization.

7. KaaIoT Core

The heart of the system: the Rule Engine handles logic, external integrations, and telemetry storage. Alerts are generated here, data is aggregated, and APIs are provided for ERP or SCADA integration.

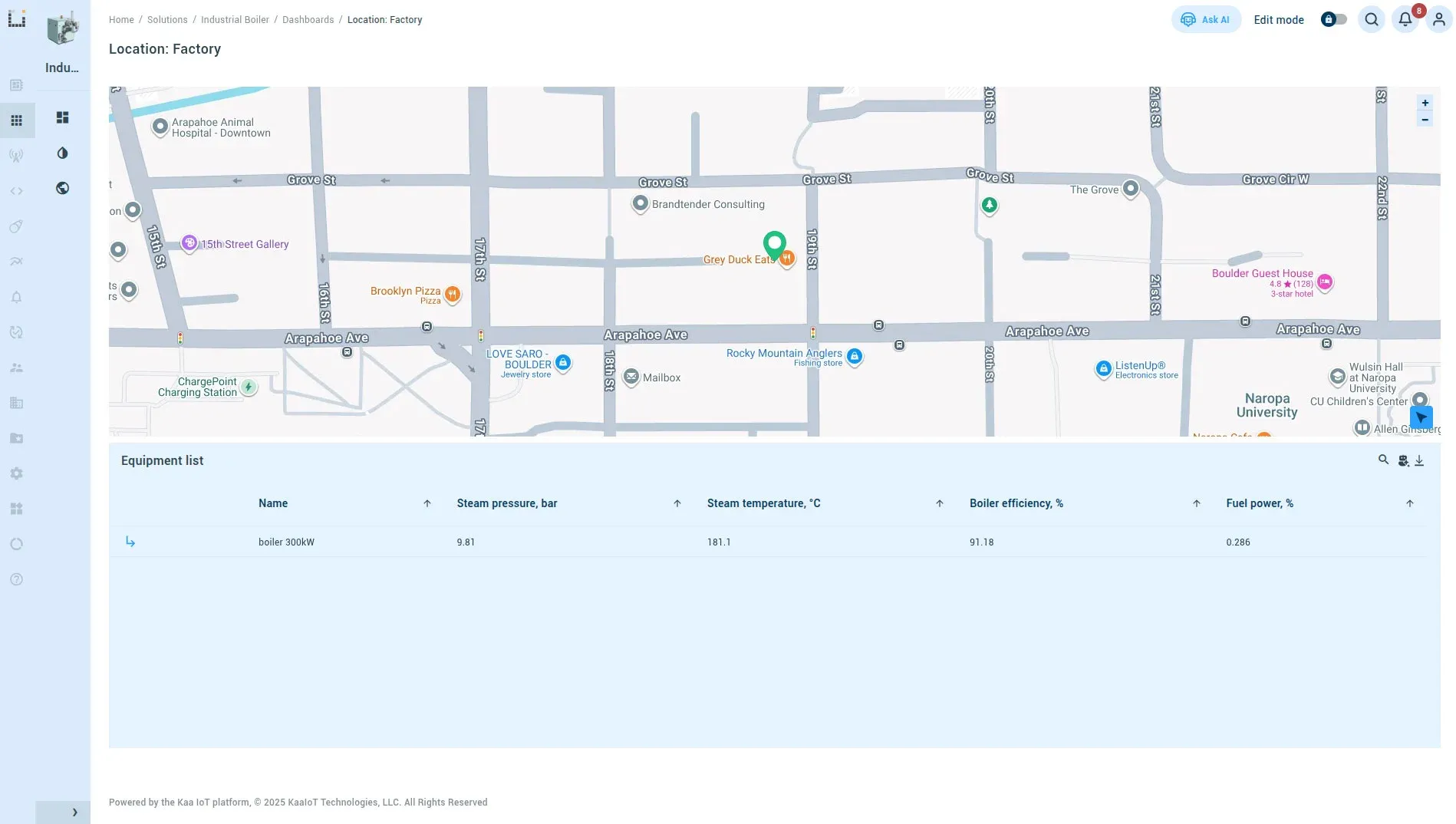

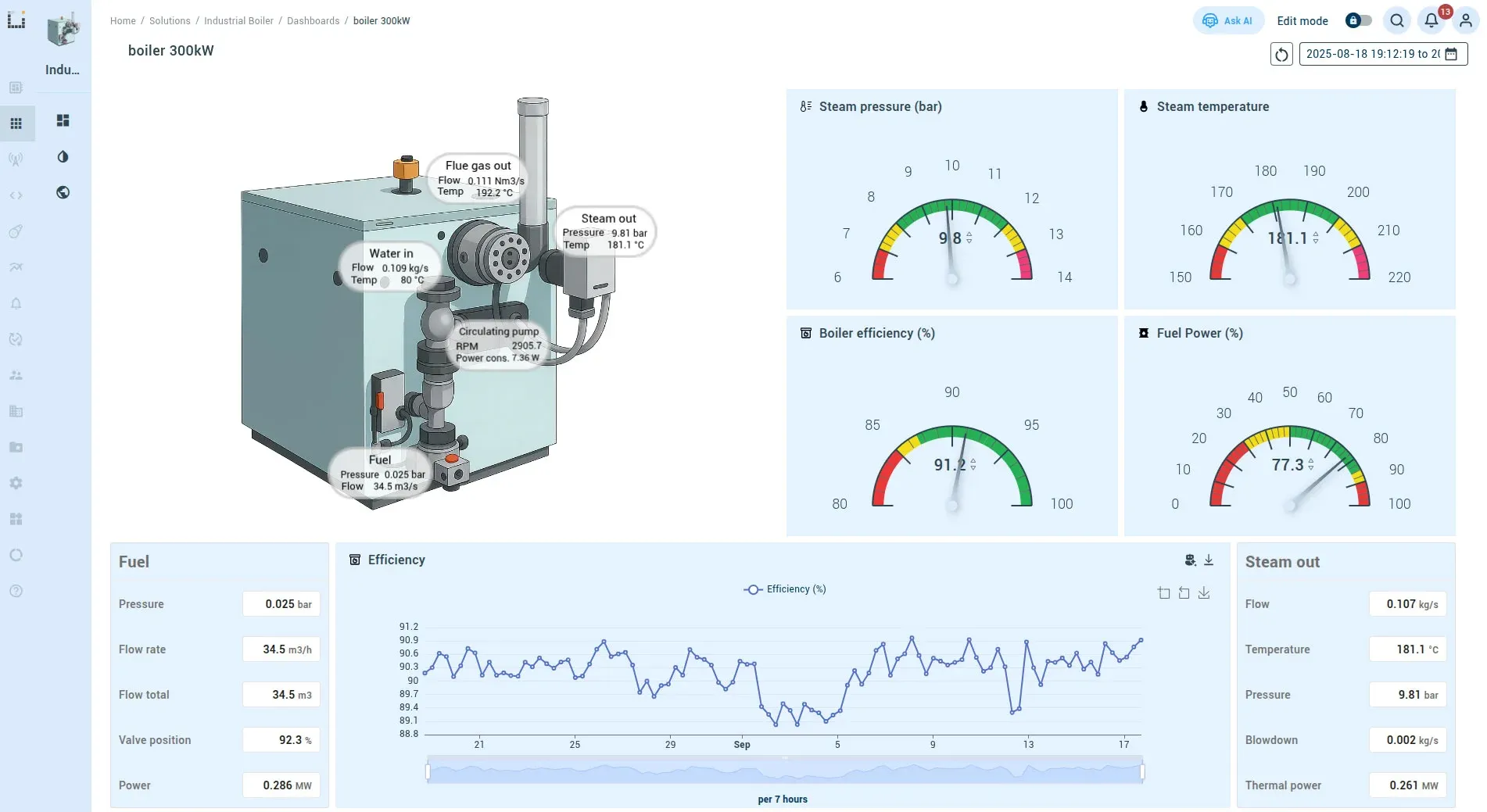

8. KaaIoT Dashboard

A web interface where engineers monitor all sites, manage equipment, and analyze data. It supports several dashboard types:

Home Dashboard – an overview of all clients and devices for service companies, or a complete equipment fleet for a single client

Sites Dashboard – a map of all locations with boiler status and filters by region or fuel type

Boiler Dashboard – a detailed view of a specific boiler: temperature, pressure, fuel and water flow, efficiency, heat losses, pump operation, live video feed, and HMI access via VNC

All dashboards are accessible from smartphones, tablets, or desktop PCs without extra software.

Metrics and Data Groups

KaaIoT collects and visualizes a broad set of data, conveniently divided into four categories.

1. Boiler Metrics

- Steam pressure (bar)

- Water and steam temperature (°C)

- Fuel and water consumption (kg/h, Nm³/h)

- Boiler efficiency and heat losses (%)

- Pump status (RPM, power consumption)

2. Access Metrics

- Door or hatch open events

- Lock and RFID reader status

- User logs for visitor tracking

3. Environmental Metrics

- Room temperature and humidity

- CO/CO₂ concentration

- Smoke or gas leak detection

4. Video and Audio Streams

- IP camera status

- Snapshots and recordings triggered by alarms

- Integration with security and archival systems

Each group supports flexible alerting channels: SMS, e-mail, phone calls, or webhooks to external services.

Security and Network Reliability

Encrypted Access with KaaIoT VPN

KaaIoT VPN provides secure, encrypted access even in environments with strict corporate firewall rules. This ensures that industrial systems remain accessible and manageable without compromising security, no matter how restrictive the network policies are.

Secure Data Exchange with MQTT over TLS

All data transfer is protected with MQTT over TLS, combined with mutual certificate authentication. This means that only devices with valid certificates are allowed to connect and read data (documentation), eliminating unauthorized access and guaranteeing trusted communication across the system.

Fine-Grained Control with RBAC and Auditing

KaaIoT also integrates role-based access control (RBAC) and auditing features. Administrators can assign granular permissions based on user roles, ensuring that individuals only access the data and functions they are authorized for. In addition, a complete activity log (audit) is maintained, providing full visibility and traceability for compliance and security auditing.

Monitoring and Notifications

KaaIoT allows engineers to configure alerts and route them through the preferred channel:

- SMS or e-mail

- Webhooks to third-party systems (allows to make automated phone calls, sending notifications to various messaging platforms, etc)

Example scenarios:

- Steam pressure rises 20 % above the threshold → immediate phone call to the on-duty engineer

- CO concentration spikes → automatic command to shut down the burner

- Door sensor triggers → camera recording starts and a push notification is sent

Real-World Deployment Example

A customer approached us with the need to replace a burner on a 500 HP Superior Boiler. Their main objectives were to boost efficiency while keeping downtime to an absolute minimum.

To meet these requirements, we installed a high-efficiency burner equipped with a Variable Speed Drive and Oxygen Trim. The system was further enhanced by integrating it with KaaIoT, enabling advanced monitoring and optimization.

The project was carefully scheduled to avoid disruption. Work began on Friday evening and, by 8 PM on Sunday, the new burner was fully installed, tested, and operational. The boiler upgrade was delivered on time, without interrupting production, and with the promised efficiency improvements.

Outcome:

- Zero safety incidents during the upgrade

- Improved combustion control and fuel efficiency

- Full real-time remote monitoring from day one

Implementation Best Practices for Remote Boiler Monitoring

To ensure reliable operation, it’s important to provide backup power for gateways and controllers. This prevents unexpected outages from interrupting data flow or device management.

For connectivity, LTE modems with a fallback option add resilience. If the primary connection fails, the system can seamlessly switch to mobile data, keeping devices online and accessible.

All equipment should also be certified for local regulatory compliance. This step reduces deployment risks and ensures smooth integration into existing infrastructure.

Finally, starting with a pilot project is the most effective approach. By connecting a single site, configuring dashboards, and testing alerts, operators can validate the setup, identify improvements, and prepare for a successful large-scale rollout.

Conclusion

KaaIoT equips engineers and service companies with a complete toolset for remote boiler monitoring and maintenance:

- Standard protocols Modbus + MQTT;

- Flexible deployment Cloud / Hosted / Self-Hosted;

- Enterprise-grade security (VPN, TLS, role-based access);

- Powerful dashboards and HMI access directly from the browser.

This solution reduces emergency visits, improves efficiency, and lowers operating costs while meeting the strictest industrial safety requirements.

Request a demo or pilot project to see how connecting industrial boilers to IoT can be straightforward, secure, and cost-effective.