Why solar panels deliver less power and how proper array voltage fixes the problem

December 01, 2025Almost everyone who installs an off-grid solar system eventually encounters the same issue: the panels are rated at 400 W, mounted correctly, facing direct sunlight, yet the system consistently delivers far below the expected output. Sometimes 300–350 W, sometimes even 250–280 W. This leads to guessing: is the weather to blame? Did the manufacturer exaggerate? Is the controller malfunctioning? In the overwhelming majority of cases, the real reason is far simpler and much less intuitive: the solar array does not supply sufficient voltage for the MPPT charge controller to operate correctly. The panels may be excellent, the sunlight strong, the cables properly sized, but if the array voltage does not exceed the battery voltage with enough margin, the system will never reach its rated power.

Modern IoT solutions for solar monitoring (IoT solar panels), including tools like an energy data logger, make this especially easy to spot: look at the PV voltage graph and you’ll see how, when the controller tries to extract maximum power, the voltage sags, the MPPT resets the charging cycle, then attempts to start again. In this mode, the actual output is always lower than the theoretical output, which confuses newcomers.

Let’s break down why this happens and why adding just one more panel can completely change the system's performance.

The main cause: low array voltage

An MPPT controller cannot extract full power from the panels if the array voltage is too low. Its job is to locate the Maximum Power Point, but it can only do this when the PV array voltage is noticeably higher than the battery voltage. For stable MPPT operation, one simple rule applies: The PV array voltage must be at least 5 V higher than the current battery voltage. If a 48 V battery bank sits between 52–56 V during charging, the array must deliver at least 57–61 V. This requirement applies to Victron, EPEVER, Growatt, and any other brand because it is defined by power-electronics physics, not manufacturer design.

When the array voltage is “on the edge,” the MPPT behaves erratically:

- it manages to start charging,

- it clamps the voltage to increase current,

- the voltage falls below the safe threshold,

- the controller drops the charge cycle and restarts.

This cyclic behavior is the fundamental reason why panels fail to reach their rated wattage. They simply cannot deliver their theoretical output until the MPPT has enough voltage overhead. This is not a hardware defect. It is a configuration issue, especially common in 48 V systems.

What happens when voltage is insufficient: voltage sag → charge reset → low output

When the panels cannot supply enough voltage, the MPPT enters a loop that destroys efficiency. The sequence looks like this:

- MPPT begins charging. The panels are barely above the required voltage, so the controller starts the process reluctantly.

- The controller clamps the voltage to raise the current. This is normal – MPPT reduces PV voltage to reach the maximum power point.

- Voltage dips below the required threshold. If the battery is at 53 V, the array must supply at least 58 V. But once clamped, the array may fall to 56–57 V, losing the required margin.

- The controller resets and restarts charging. To the user, the system appears to “breathe”: charge ramps up, collapses, then restarts.

- The system never reaches its rated power. The inverter oscillates between short bursts of output and extended periods of inactivity.

In telemetry, this appears as unstable power curves, low peaks, the feeling that panels operate “at half capacity, and visible oscillations in IoT monitoring or an energy data logger. This is not a problem with the panels, the controller, or sunlight; it is purely a configuration issue: insufficient array voltage.

Real example: how a single additional panel doubled the output

Consider a typical 48 V setup. The owner installed two 400 W panels, each producing roughly 30 V. In series, they provided up to 60 V. At first glance, this seems sufficient: a 48 V battery and a 60 V array, seemingly enough overhead. But the system behaved differently.

Stage 1. Two panels: voltage on the edge:

- 2 × 400 W panels

- array voltage: ~60 V

- battery voltage: 50–56 V

- minimum required array voltage: 55–61 V

What happened?

The panels provided adequate voltage only until the MPPT started clamping to increase current. As soon as that happened, the array voltage dropped to 57–58 V, not enough to continue charging when the battery sat at 53–54 V. The controller reset repeatedly. As a result, the system produced only 460–500 W. With a theoretical 800 W array, the system delivered only about half its potential due to insufficient voltage overhead.

Stage 2. Adding a third panel: voltage rises to ~90 V

When a third panel was added in series:

- array voltage increased to ~90 V,

- the MPPT had ample overhead,

- voltage no longer sagged below the threshold,

- charging stabilized completely.

The output jumped to 1387 W. The system finally operated at full capacity because the MPPT could maintain the maximum power point without collapsing voltage. Nothing else changed: not sunlight, not wiring, not the inverter. The only difference was the voltage reserve. That alone transformed the system’s performance.

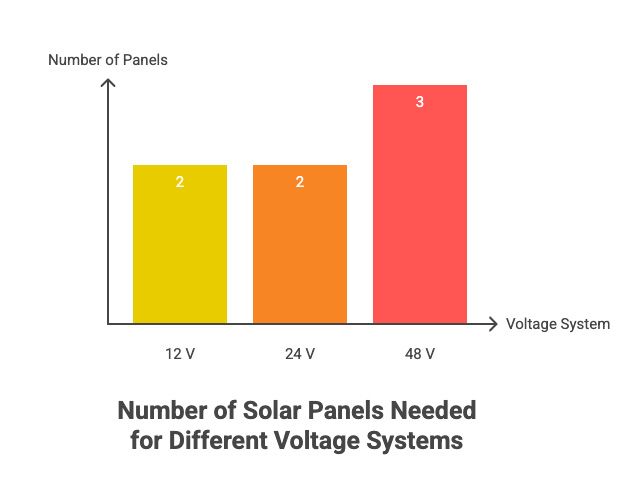

How many panels you need for 12/24/48 V systems

The number of panels in series must provide a guaranteed voltage overhead. A simple, reliable rule applies:

12 V systems – 2 panels in series.

24 V systems – 2 panels (one only in rare cases).

48 V systems – minimum 3 panels.

This is not a “safety margin.” It is a fundamental electrical requirement related to the rise in battery voltage during charging. Panels must be able to maintain array voltage above the battery even when the MPPT actively lowers PV voltage to increase current. If this condition is not met, system performance will be unstable regardless of brand.

You may be interested in: Choosing the right data logger for your PV system

Monitoring the system with IoT: detecting issues early

Even a correctly wired system benefits from continuous monitoring. Without it, owners may miss PV voltage dips, MPPT resets, battery overvoltage/undervoltage conditions, partial shading effects, cable or connector losses. This is why IoT monitoring for solar systems is becoming standard. It enables real-time visibility into PV array voltage, panel current and actual output, MPPT behavior under load, battery conditions during charging, sudden drops caused by shading or thermal derating. If the array configuration is incorrect, for example, only two panels are used in a 48 V setup, so the problem becomes visible immediately: voltage collapses appear regularly, and the power curve forms a distinctive “sawtooth” pattern.

Also, the Kaa energy data logger comes into play, providing full IoT telemetry for the solar system. It:

- captures data from the panels, controller, and batteries,

- logs voltage, current, power, and MPPT efficiency,

highlights voltage dips during MPP tracking,

sends alerts when the array is misconfigured,

helps quickly identify the root cause of low performance.

In essence, it becomes the system’s “black box”: you can see exactly what prevents the panels from reaching their rated output: overheating, shading, poor connections, or insufficient array voltage. This is especially valuable for remote installations where physical checks are difficult.

Conclusion

Solar panels rarely underperform due to defects. Most cases of low output are caused by one simple factor: the array voltage is insufficient for stable MPPT operation, the controller enters repeated reset cycles, and the system never reaches its theoretical wattage. Adding the correct number of panels in series allows the system to operate as intended. Proper array configuration, combined with monitoring via an energy data logger, provides full visibility into system behavior and makes troubleshooting straightforward. The key message is that in 90% of cases, solar panels perform exactly as rated; they simply need the correct voltage and proper array configuration.