Liquid level monitoring with Milesight sensors and KaaIoT

October 09, 2025In modern industrial systems, accurate liquid level control plays a critical role. The stability of this parameter directly affects safety, efficiency, and equipment longevity. Such systems are used across a wide range of industries — from water supply and fuel storage to chemical production and agriculture. Wherever tanks or reservoirs are used, it is essential not only to know the liquid volume but also to automate filling, draining, and emergency shutoff processes.

Traditional liquid level measurement methods, such as float or hydrostatic sensors, have been used for decades but come with several limitations. Mechanical components are prone to wear, corrosion, and contamination, especially in aggressive environments. In addition, their installation and maintenance require physical contact with the liquid, which complicates operation and increases failure risks.

For these reasons, non-contact measurement technologies are gaining increasing attention. Distance sensors — ultrasonic, laser, or optical — can determine liquid levels without direct contact with the surface. This approach eliminates exposure of the sensor to harsh media, simplifies installation, improves reliability, and reduces maintenance costs.

The development of Internet of Things (IoT) technologies has opened new opportunities for integrating such sensors into intelligent monitoring and automation systems. Now, level control can become part of a unified digital solution: real-time data from sensors are transmitted to a platform, where they are analyzed, visualized, and used for equipment control — such as pumps, valves, and alert systems.

This article presents a practical implementation of such a system based on Milesight sensors (in particular, the EM400-MUD and EM400-UDL models) combined with the KaaIoT cloud platform. We demonstrate how these technologies enable the creation of a reliable, scalable, and easy-to-deploy liquid level monitoring system suitable for industrial, infrastructure, and agricultural applications.

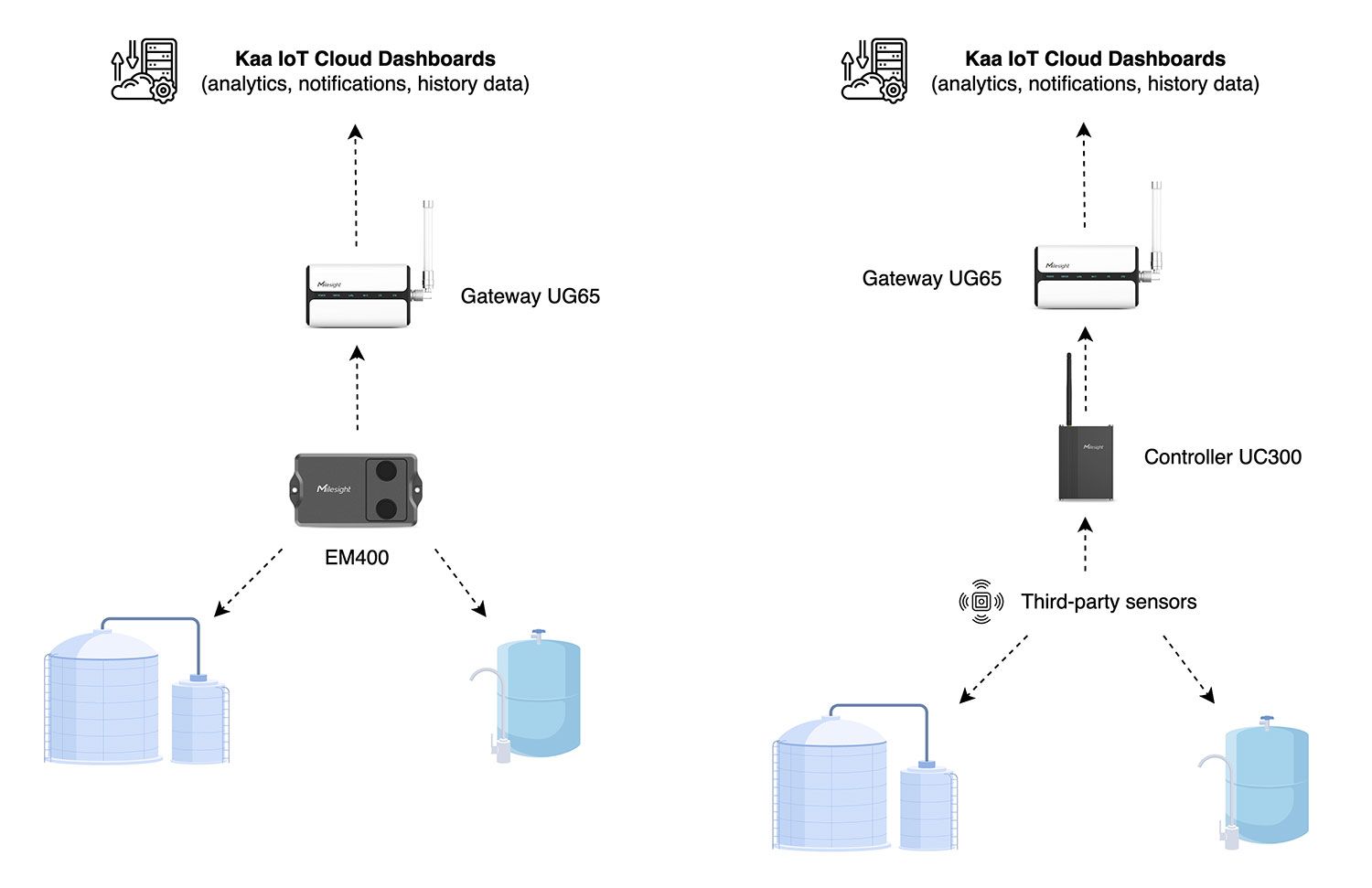

System Architecture: Milesight + KaaIoT

The liquid level monitoring system is built on Milesight hardware and includes three key components:

- the EM400-UDL ultrasonic sensor for measuring the level of water, fuel, fertilizers, or chemicals;

- the UC300 controller for local data processing and actuator control;

- and the UG65 gateway, which provides wireless data transmission over LoRaWAN to the cloud platform.

1. Sensor Installation

The system can be implemented in two configuration options.

In the first, the Milesight EM400-UDL ultrasonic sensor is mounted on top of the tank. It performs non-contact level measurement (for water, fuel, fertilizers, or chemicals) and outputs a digital distance value.

In the second scenario, third-party sensors are used — devices from various manufacturers that operate via Modbus RTU, analog inputs (4–20 mA, 0–10 V), or dry contacts. These sensors are connected to the Milesight UC300 controller, which digitizes and normalizes the data before transmission to the network.

2. Data Collection and Transmission

In both configurations, LoRaWAN serves as the main communication channel.

In the first setup, the EM400-UDL transmits data directly to the UG65 gateway, which aggregates and forwards the measurements to the cloud. In the second, sensors send their readings to the UC300 controller, which forms telemetry packets, executes basic control logic, and relays results to UG65. The UG65 gateway then transmits the data via Ethernet or LTE, acting as the intermediary between field devices and the cloud platform.

3. Data Processing in KaaIoT

Once data are received by the UG65, they are transmitted to the KaaIoT cloud platform for processing, visualization, and storage. The platform displays real-time liquid levels, device states, and historical data trends. Users can configure iot dashboards, define threshold values, and create automatic response scenarios — for instance, activating pumps or triggering alarms. All data are securely stored in the cloud and accessible through a web interface or API.

4. Alerts and Monitoring

KaaIoT provides centralized monitoring of all devices and events within the system. When abnormal conditions are detected — such as a sudden level drop, loss of sensor connection, or suspected leak — an alert is automatically generated with timestamp, device ID, and parameter value. Notifications can be sent via email, SMS, or integrated alerting systems. Dashboards provide a consolidated overview of all tanks and enable rapid response to operational anomalies.

Advantages of the Milesight + KaaIoT Solution

1. Non-contact Measurement and High Reliability

A key advantage of the system is the use of ultrasonic non-contact level measurement. The sensor does not touch the liquid, eliminating corrosion, mechanical wear, and exposure to aggressive media. With no moving parts, the devices offer longer lifespan and reduced maintenance costs. This ensures stable readings even under harsh conditions — such as when monitoring fuel, fertilizers, or chemical solutions.

2. Secondary Diagnostic Parameters

Milesight sensors provide not only level readings but also secondary parameters such as temperature and tilt. These help diagnose sensor condition and detect potential issues before failures occur. For example, a change in tilt angle may indicate mounting displacement, while temperature anomalies could point to overheating or enclosure damage. This built-in self-diagnosis capability enhances overall measurement accuracy and system reliability.

3. Long-term Autonomous Operation

Thanks to low power consumption and lithium battery technology, Milesight devices can operate autonomously for up to 10 years without battery replacement. This makes them ideal for distributed or remote assets, such as fuel tanks or agricultural reservoirs, where regular maintenance is impractical. Minimal servicing requirements reduce total cost of ownership and simplify large-scale deployments.

4. Deployment Flexibility

Wireless communication over LoRaWAN or NB-IoT enables flexible sensor placement without the need for cabling. This simplifies installation on existing sites and allows the system to scale rapidly as new measurement points are added. Support for standard interfaces also ensures seamless integration with existing IoT or SCADA infrastructures.

5. Centralized Management and Analytics

The KaaIoT cloud platform provides a complete data management cycle — from acquisition and visualization to automation logic. Users can access centralized dashboards, analytics reports, and measurement histories. The system supports event-driven workflows, automatic equipment control, and multi-channel alerting, enabling intelligent real-time process management.

6. Integration with Actuators

The Milesight + KaaIoT solution goes beyond measurement. Through compatibility with controllers and actuators, it supports automated control of pumps, valves, and other field devices. Reactive logic implemented in KaaIoT enables automatic responses to level changes, leaks, or alarms. As a result, the system functions not only as a monitoring tool but as a fully integrated element of industrial automation.

Conclusion

The Milesight + KaaIoT system delivers reliable, automated liquid level monitoring by combining sensors, gateways, and cloud analytics into a unified infrastructure. The solution is scalable, resilient to environmental conditions, and ready for industrial deployment.

Integration of measurement devices with an IoT platform allows not only real-time data tracking but also process control — including pumps, valves, and alarm systems. This increases operational efficiency and reduces human involvement.

For organizations interested in evaluating the system’s capabilities, we can provide a live demo featuring connected Milesight devices and online access to the KaaIoT dashboard to showcase its performance and integration potential.