How IoT scenting reduces material overconsumption

January 12, 2026Material overconsumption is a common but often overlooked issue in commercial scenting deployments. Traditional aroma delivery relies on fixed timers, manual calibration, and assumptions about space usage, which frequently leads to excessive fragrance consumption, inconsistent scent levels, and unnecessary operating costs. Provided that sustainability and cost efficiency become measurable business priorities, companies are rethinking how scenting systems are managed.

IoT scenting introduces a data-driven approach to fragrance delivery by replacing static configurations with adaptive control. Instead of continuous or overestimated diffusion, connected platforms enable precise scent dosing based on real usage patterns, zones, and schedules. This allows organizations to maintain a consistent sensory experience and significantly reduce material waste. Modern smart scenting systems also provide transparent monitoring and analytics, transforming fragrance consumption from an estimated expense into a measurable, optimizable resource. Beyond cost savings, this level of control supports ESG reporting and broader sustainability objectives, making scenting part of an accountable operational strategy rather than a blind operational cost.

Why material overconsumption is a hidden cost in scenting systems

In many commercial environments, fragrance systems operate with limited visibility and minimal feedback. Fixed diffusion intervals and uniform intensity levels assume constant demand, regardless of actual occupancy or airflow conditions. As a result, fragrance is often released when it delivers little or no value, leading to systematic overconsumption.

This inefficiency has direct financial implications. Excessive use of fragrance concentrates increases procurement and logistics costs, while uneven scent distribution can trigger complaints or require manual recalibration. Indirectly, overuse also contributes to higher packaging waste and more frequent servicing, which further increases operational overhead. Perhaps most importantly, overconsumption does not improve scent quality. Higher output does not translate into better perception – it often causes saturation, faster olfactory adaptation, and discomfort. Without precise control, organizations end up paying more for results that are less consistent and harder to manage.

How IoT enables precise, demand-based scent dosing

Conventional scenting systems typically rely on static logic: predefined schedules, fixed diffusion durations, and manual tuning. IoT-based architectures fundamentally change this model by introducing continuous control and feedback into fragrance delivery. At the core of IoT scenting is the ability to align diffusion with demand signals rather than assumptions. Connected devices adjust output dynamically based on configurable rules or live inputs, such as time-of-day profiles, zone-specific requirements, or integrations with building systems, such as HVAC or occupancy sensors. Fragrance is released only when and where it is actually needed. Precise scent dosing replaces coarse on/off cycles with fine-grained control. Instead of compensating for uncertainty by increasing output, operators define narrow dosing thresholds that maintain a stable sensory effect while minimizing liquid consumption. This approach improves predictability and reduces waste without degrading experience.

Key parameters controlled by IoT-based scent dosing

IoT-enabled scenting platforms manage fragrance output using tightly defined, measurable parameters:

- Diffusion intensity – controls the amount of fragrance released per cycle;

- Activation duration – limits how long diffusion runs;

- Emission frequency – replaces continuous output with controlled bursts;

- Zone-level configuration – applies different dosing profiles per area;

- Time-based profiles – aligns scenting with operating hours and peak periods;

- Centralized rule management – enables remote updates across multiple sites.

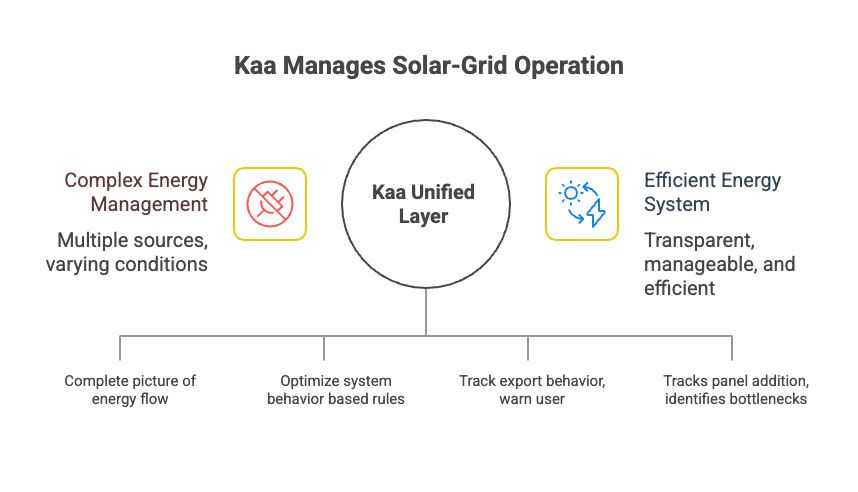

Together, these controls turn scenting into a deterministic, repeatable process. Fragrance consumption becomes predictable, auditable, and materially more efficient. This type of demand-based control is typically implemented through centralized IoT platforms. For example, Kaa’s scent management solution enables rule-based dosing, zone-level configuration, and remote updates across distributed scenting deployments, ensuring consistent behavior without manual recalibration.

Reducing fragrance liquid consumption without compromising experience

A common concern around optimization is the assumption that reduced consumption leads to weaker or inconsistent scent perception. In reality, excessive diffusion is often the cause of poor experience rather than its solution. IoT-based scenting focuses on controlled exposure instead of volume. Short, well-timed diffusion cycles maintain perception without oversaturating the space. This is particularly effective in environments with variable airflow, temperature changes, or fluctuating occupancy, where a static output can lead to uneven results.

Smart scenting systems allow operators to adapt fragrance delivery to real conditions. High-traffic periods can be supported with slightly increased output, while low-usage windows rely on minimal or no diffusion. Zone-level control prevents overuse in transitional or low-impact areas where full-strength scenting provides no measurable benefit. The outcome is a shift from volume-driven to perception-driven scenting. Consumption decreases not because the system does less, but because it does exactly what is required – no more, no less.

Monitoring, analytics, and transparency in fragrance usage

Without measurement, fragrance consumption remains an estimated cost rather than a controllable variable. Traditional setups provide little insight beyond refill frequency, making it difficult to detect inefficiencies, leaks, or systematic overdosing. IoT-based scenting introduces continuous monitoring at the device, zone, and site levels. Consumption data is recorded over time, enabling trend analysis instead of reactive observation. Abnormal depletion rates or unexpected spikes become visible immediately rather than weeks later.

Scenting analytics support ongoing optimization. Operators can compare usage across locations or time periods, identify inefficient configurations, and adjust dosing rules with precision. Centralized dashboards replace manual logs and fragmented reports, ensuring decisions are based on consistent, verifiable data. For multi-site deployments, this transparency is critical. Fragrance usage becomes auditable and predictable, supporting internal accountability and external reporting requirements.

ESG reporting and sustainability benefits of IoT-based scenting

As ESG frameworks increasingly emphasize measurable outcomes, untracked material consumption becomes a liability. Even though scenting may account for only a small share of total resource use, uncontrolled overconsumption contradicts sustainability goals related to efficiency, waste reduction, and transparency. By monitoring actual fragrance usage, organizations can document material efficiency improvements rather than rely on estimates. Reduced overconsumption leads to lower chemical usage, fewer refills, and less packaging waste – all of which contribute to environmental performance indicators.

From an ESG perspective, IoT scenting provides traceability. Usage data can be aggregated by site or reporting period, supporting internal sustainability reviews and external disclosures. Scenting operations align with the same data-driven accountability already applied to energy, water, or HVAC systems.

You may be interested in: Scenting applications for businesses

Conclusion

IoT-based scenting replaces assumption-driven diffusion with controlled, data-backed operation. Through precise scent dosing, organizations reduce overconsumption of fragrance liquid while maintaining a consistent sensory experience. Beyond cost savings, transparent consumption data supports ESG reporting and sustainability initiatives. Fragrance usage becomes measurable, auditable, and defensible rather than inferred from manual checks.

Ultimately, IoT scenting is not about reducing output at the expense of experience. It is about delivering exactly what is required, where and when it adds value – turning scenting into a predictable, efficient, and responsible operational process.