Best gateways for industrial boiler control systems

September 30, 2025Unplanned boiler failures cost facilities hundreds of thousands of dollars per day in downtime, energy waste, and emergency repairs. In manufacturing, chemicals, and food processing, boilers are among the most critical and most energy-intensive assets. They supply the steam and hot water that keep operations running, and any outage directly impacts safety, compliance, and profitability. The challenge is that most boilers still operate in isolation. Legacy controls and proprietary protocols make it difficult to connect them with modern building automation systems (BAS), industrial IoT platforms, and enterprise dashboards. Without this integration, operators lack real-time visibility, predictive maintenance opportunities, and advanced energy management.

This is where boiler gateways play a crucial role. Acting as communication bridges, they translate protocols into IoT-ready formats, enabling secure remote monitoring and integration into enterprise platforms. Let’s break down what to look for in a gateway, compare the leading solutions available in 2025, and explain how KaaIoT can help unify them into a secure, analytics-ready system.

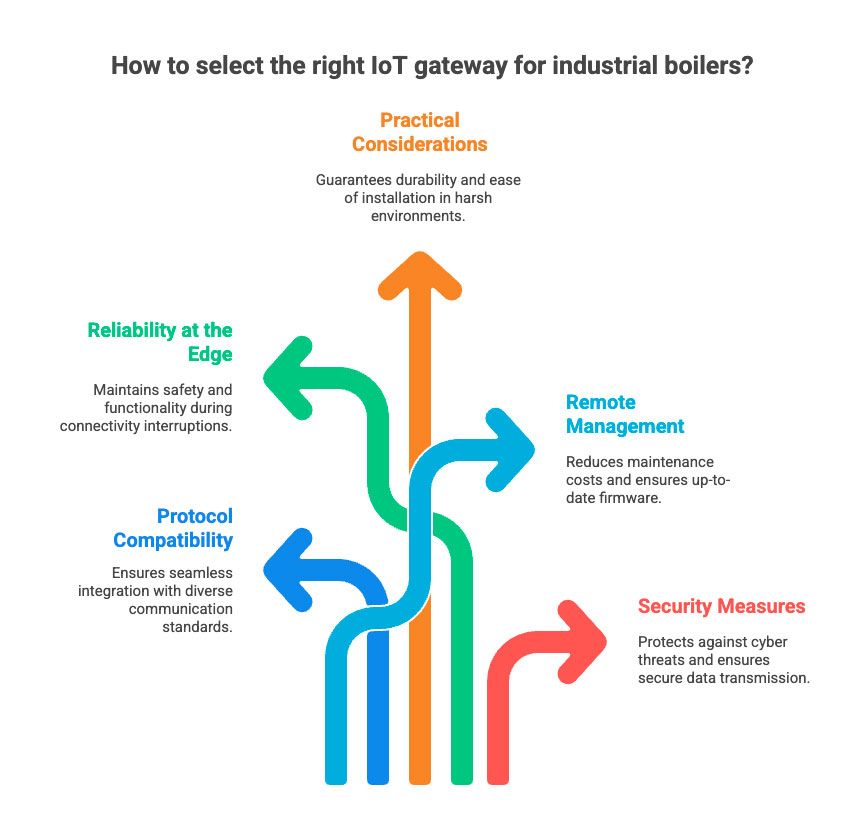

What to look for in a boiler gateway

Not all IoT gateways are built with industrial boiler environments in mind, so it is essential to evaluate them against specific requirements. A robust gateway must handle diverse communication standards such as Modbus RTU/TCP, BACnet MSTP/IP, OPC UA, and OEM-specific protocols, translating them into cloud-ready formats like MQTT or HTTPS. Beyond protocol conversion, reliability at the edge is equally important. The best devices can filter out noisy data, buffer readings during connectivity interruptions, and execute local logic such as alarms or sequencing commands to keep boilers safe even if cloud links fail.

Practical considerations also weigh heavily in the decision. Industrial boiler rooms are hot, humid, and electrically noisy environments, which means gateways need to be ruggedized, DIN-rail mountable, temperature-rated, and certified for industrial use (CE, UL, FCC). Remote management capabilities, including OTA firmware updates, centralized configuration, and diagnostic tools, reduce on-site maintenance and keep deployments cost-effective. Finally, because gateways sit at the intersection of operational and IT networks, they must provide strong security measures such as TLS encryption, VPN tunneling, and certificate-based authentication, reinforced by role-based access controls. These factors distinguish purpose-built boiler gateways from generic IoT hardware and determine whether a deployment will remain safe, scalable, and efficient over time.

Top boiler gateways in 2025

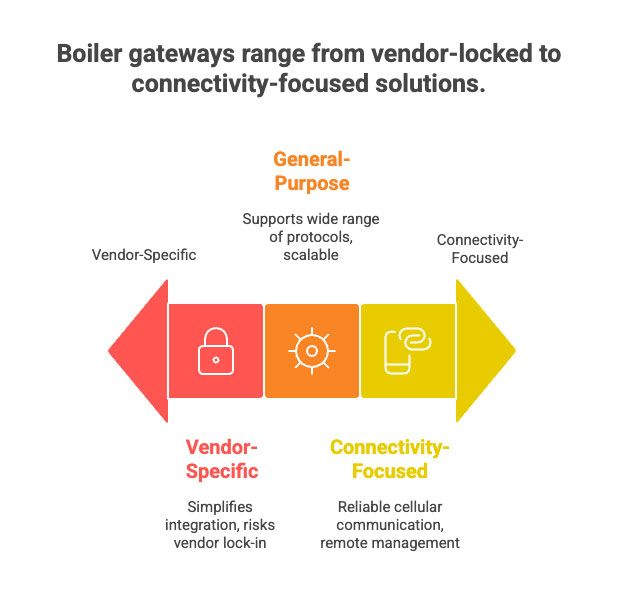

Boiler gateways on the market today fall broadly into three categories. Vendor-specific gateways are provided by boiler OEMs and give the fastest route to connect their equipment into building management systems. General-purpose industrial IoT gateways are vendor-neutral and support a wide range of protocols, making them suitable for plants running different boiler brands or pursuing enterprise-wide digital strategies. A third group, connectivity-focused gateways, is optimized for distributed fleets where reliable cellular communication is more important than broad protocol support.

To summarize at a glance:

- Vendor-specific gateways simplify OEM integration but risk vendor lock-in.

- General-purpose and connectivity-focused gateways offer flexibility and scalability for multi-brand or distributed deployments.

Vendor-specific boiler gateways

Several OEMs provide their own gateways to simplify integration.

AERCO offers the ProtoNode and ProtoAir, which support BACnet/IP, BACnet MSTP, Modbus RTU/TCP, and LonWorks. These devices are widely deployed in hospitals, universities, and commercial complexes running AERCO systems, with ProtoNode providing wired Ethernet and ProtoAir offering Wi-Fi for easier retrofits. LAARS provides a Multi-Protocol Gateway that supports Modbus and BACnet while adding built-in sequencing logic, which is especially valuable in schools, apartment complexes, or municipal facilities operating multiple boilers in parallel. Similarly, NTI’s BMS Gateway focuses on BACnet/IP and MSTP, making it a practical option in office towers and government buildings where BACnet dominates.

While these OEM devices reduce integration time and risk, their usefulness drops in mixed fleets, and they often create vendor lock-in.

At a glance:

- Best for single-brand facilities.

- Simplifies integration but creates long-term inflexibility.

General-purpose industrial IoT gateways

For enterprises managing diverse assets or seeking enterprise-wide integration, general-purpose gateways provide a more flexible solution.

Advantech gateways support Modbus, BACnet, OPC UA, MQTT, and REST APIs, all in ruggedized hardware designed for harsh industrial conditions. They are common in energy plants and heavy industry where boilers are only one part of a larger infrastructure. HMS Networks, through Anybus and eWON, specializes in protocol conversion and secure remote access, offering built-in VPN capabilities that appeal to service providers managing multi-brand fleets across multiple sites. Siemens’ IoT2040 series goes further, functioning as industrial PC-class gateways with local analytics and anomaly detection capabilities. They are often integrated with Siemens’ MindSphere platform, supporting digital twin and smart factory projects.

These gateways require more configuration than vendor-specific models, but they deliver scalability, vendor neutrality, and edge intelligence that align with long-term IoT strategies.

At a glance:

- Best for multi-brand fleets and enterprise rollouts.

- More complex to deploy but future-proof and scalable.

Connectivity-focused gateways for distributed fleets

In many projects, the main challenge is not protocol conversion but reliable connectivity. Utilities, district heating providers, and service companies often operate boilers spread across multiple sites, sometimes in remote buildings with no wired internet. For these cases, cellular-first gateways offer a practical solution. Their strength lies in secure communication, remote management, and cost-effective deployment rather than deep BAS integration.

Teltonika’s RUT series combines ruggedized design with support for Modbus and MQTT, offering VPN tunneling and centralized remote management that simplify large-scale deployments. MikroTik LTE/5G gateways provide advanced routing, VPN, and firewall functions at competitive cost, and can even run custom scripts or lightweight containers – a feature appreciated by integrators seeking flexibility. The BLIIoT S275 combines Modbus and MQTT support with 4G/5G connectivity, while also offering cloud-ready features such as alarm notifications and OTA updates, making it well suited for multi-building fleets.

Connectivity-first gateways excel in remote monitoring scenarios, ensuring that data is transmitted securely and reliably even without wired networks. With platforms like KaaIoT, they enable real-time dashboards, centralized fleet management, and predictive analytics without requiring local IT infrastructure.

At a glance:

- Best fit for distributed fleets without stable wired internet.

- Strength lies in cellular connectivity and remote management, not deep protocol conversion.

Gateway comparison table

| Category | Vendor-specific | General-purpose | Connectivity-focused |

|---|---|---|---|

| Example devices | AERCO ProtoNode/ProtoAir, LAARS Multi-Protocol, NTI BMS Gateway | Advantech, eWON, Siemens IoT2040 | Teltonika RUT, MikroTik LTE/5G, BLIoT S275 |

| Protocols | Modbus RTU/TCP, BACnet MSTP/IP, LonWorks (varies) | Modbus, BACnet, OPC UA, MQTT, REST APIs | Modbus (varies), MQTT |

| Connectivity | Ethernet, some Wi-Fi | Ethernet, Wi-Fi, Cellular (model-dependent) | Ethernet, Wi-Fi, 4G/5G |

| Strengths | Simplifies OEM boiler integration; sequencing support | Multi-protocol, vendor-neutral, edge compute | Reliable cellular connectivity; cost-effective |

| Limitations | Locked to single vendor; poor fit for mixed fleets | Higher setup effort and cost | Limited BAS integration; narrow scope |

| Best use cases | Sites standardized on one boiler brand | Plants with multi-brand fleets; enterprise IoT | Utilities, district heating, service providers |

| KaaIoT integration benefits | KaaIoT aggregates OEM data, adds analytics, and extends monitoring beyond vendor controllers | KaaIoT normalizes heterogeneous data, supports digital twins, and enables unified dashboards | KaaIoT leverages MQTT streams for cloud dashboards, remote alarms, and OTA fleet management |

You may be interested in: Critical data points in boiler remote monitoring.

Best practices for deployment

Selecting the right gateway is only part of the equation. Deployment strategy is equally important.

- Match gateway to brand and protocols; vendor gateways are most suitable for single-brand facilities, while multipurpose devices are better suited for mixed fleets. Example: a university avoided vendor lock-in by using multipurpose gateways across different boiler types.

- Assess the environment. Choose gateways with industrial certifications and extended temperature ranges to ensure optimal performance. Example: a food processor doubled device life by moving to rugged DIN-rail units.

- Pilot remote diagnostics. Test OTA updates, alarm reporting, and configuration tools before scaling. This prevents costly rework when managing dozens of gateways.

- Enforce cybersecurity – Use TLS, VPNs, and certificates. Follow frameworks such as IEC 62443 or NIST. Gateways are frequent entry points for cyberattacks.

- Plan for scalability. Ensure multi-boiler sequencing or OTA fleet management is supported. This avoids efficiency losses and simplifies future expansion.

Why it matters: Boiler gateways sit at the OT-IT boundary, which makes them both powerful and vulnerable. Studies suggest nearly 70% of industrial organizations faced at least one OT-related cybersecurity incident in the past year, often linked to weak gateway security. Careful deployment prevents downtime, enhances safety, and supports long-term energy efficiency.

For a deeper dive into boiler system connectivity and design, see our overview of industrial boiler IoT architecture.

Conclusion

Boiler gateways are the foundation of digital boiler operations. They ensure interoperability, enable secure connectivity, and provide the data streams needed for predictive maintenance and efficiency optimization.

- Vendor-specific gateways simplify OEM integration.

- General-purpose gateways provide flexibility for mixed fleets.

- Connectivity-focused gateways make remote monitoring practical.

On their own, gateways provide connectivity. With KaaIoT, gateways become part of a full ecosystem for remote industrial boiler monitoring and maintenance, reducing the need for emergency service calls:

- Standard protocol support (Modbus, BACnet, MQTT, OPC UA);

- Flexible deployment (Cloud, on-premises, or hybrid models);

- Enterprise-grade security (VPN tunneling, TLS encryption, role-based access);

- Advanced dashboards & HMI access (unified boiler insights in real time).

Combining these capabilities, KaaIoT reduces emergency visits, extends equipment life, and ensures safe, compliant, and efficient boiler operations. Request a demo or pilot project today to see how connecting boilers with KaaIoT can be straightforward, secure, and cost-effective.